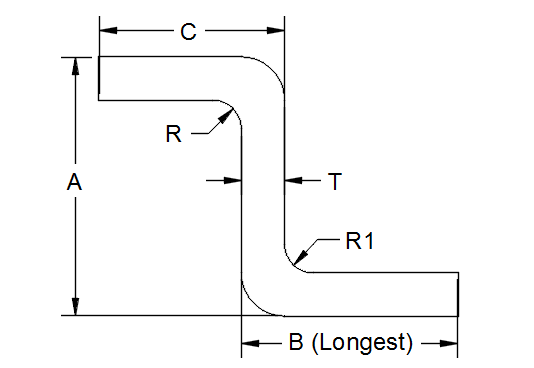

Aluminum Formed Z-Section

Description

Aluminum Formed Z-Section is an aerospace shape that is formed from an aluminum sheet, either roll formed or brake formed. They are used in the manufacture and repair of commercial and military aircraft. Material produced and stocked by Aircraft Extrusion Co in 2024, 7075 and 6061 aircraft alloys and are supplied with full test reports to aircraft and FAA specification of AMS-QQ-A-250/4-2024-T42 BARE, AMS-QQ-A-250/5-2024-T42 CLAD, AMS-QQ-A-250/12-7075-T62 BARE, AMS-QQ-A-250/13-7075-T62 CLAD. Aircraft Extrusion Co is AS9100 Rev C and ISO9001:2008 certified company.

How to use our search tool for Aluminum Formed Z-Section

The data table has some powerfull tools to help you search through Aluminum Formed Z-Section. Using the sort function and filters, we provide a unique user experience taking the hastle out of finding extruded shapes to funnel down, not just to the best fit extrusion, but a profile that is either available from stock or an item that we are tooled for.

Services and processes for your Aluminum Formed Z-Section

Aircraft Extrusion Company offers CNC Machining, Forming, Rolling and Shrinking of aerospace profiles. Our fast turn around times are days, not weeks. Custom tooling and expert team of fabricators and engineering prove a single source for material processing and handling.

New OEM Parts

Aerospace Extrusion technology has grown. Today we can extrude as little as 12ft within 5 weeks with your custom design. Our CAD team provide quotes within one day. Pricing is exceptionally competative. Our die charges start at $325.00 for a new die. Unlike soft alloys like 5052, 6061, Aerospace alloys have to be extruded on special machines. Mechanical properties have to be locked in during the heat treatment process, then we test material for dimentional tolerance, mechanical and chemical composition. All our aerospace profiles are supplied with full certification and qualified for all major specifications including AMS, QQA, WWT amd AMS specifications.