Cargo Nets, Restraints, Design and Mfg.

End to End Projects - 3D designed and Manufactured.

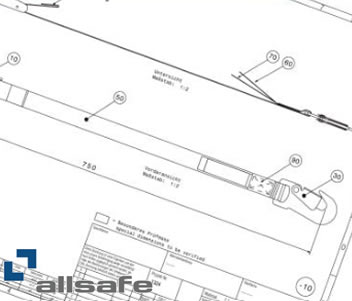

Cargo Nets and Restraints

Cargo Restraint

Textile products for cargo restraint. allsafe provides a complete textile solution for cargo restraint systems in aircraft. System developement includes customer specific textile solutions as well as indivisual tracks, anchor plates, fittings and buckles.

Custom Straps made to order

allsafe Textile Products offers a range of high-quality, durable fabrics designed for safety and protection. Specializing in flame-resistant and antimicrobial textiles, allsafe ensures compliance with industry standards. Their products are ideal for various applications, including industrial, healthcare, and hospitality sectors, providing reliable and effective protective solutions.

Aligning AEC and allsafe

As Aircraft Extrusion company expands, a question we are consistently asked what is the availability of fittings that are NOT made in China. AEC is proud to announce that as an authorized distributer for allsafe products in Germany we can now offer a complete vertically integrated line of aircraft fittings made to aerospace specifications with full traceability.

Allsafe Quality Approvals

As a partner in aerospace Allsafe is committed to excellence. All items sold through Aircraft Extrusion Company include certification to AS9100:2018 and ISO9001:2015. Additional approvals include EASA APODA, Part 21 Section A Subpart G and Part 145 C6 are the proof.