Aircraft Seat and Cargo Tracks, Design and Mfg.

End to End Projects - 3D Designed and Manufactured.

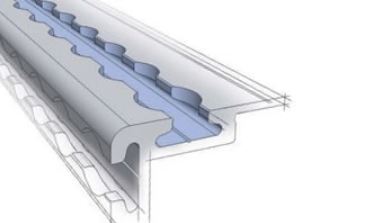

Seat & Cargo Track Extrusion (Rails)

7075 Seat Tracks for Boeing A/C

Boeing seat tracks set the industry standard for reliability and performance. Engineered with advanced materials and precision manufacturing, they ensure secure attachment of seats in Boeing aircraft. Trusted by airlines globally, Boeing seat tracks guarantee passenger safety and comfort, making them an essential component of every flight.

Custom Design

With no minimum order, Aircraft Extrusion Co can design, extrude and include the seat slots ready for install. All holes are drilled to the standard AS33601 or MS33601. Generally manufactured in 12ft lengths we can make to you exact length up to 75FT.

Seat Tracks in aircraft grade aluminum

Aircraft Extrusion Company delivers top-notch seat tracks, crucial for aircraft interiors. Crafted with precision from high-grade materials, these tracks ensure safety and comfort for passengers and crew. Their lightweight yet durable design withstands rigorous flight conditions, meeting stringent aviation standards. With a commitment to excellence, Aircraft Extrusion Company provides reliable solutions, elevating the quality and performance of aircraft interiors worldwide.

Aircraft Extrusion Co AS9100

AEC is an aerospace extrusion distributor based in Chico, CA. We are AS9001 and ISO9001:2015 Certified. We specialize in extruded shapes in 2024, 6061 and 7075. With no minimum order we can provide the best lead times and best pricing. Call us today!